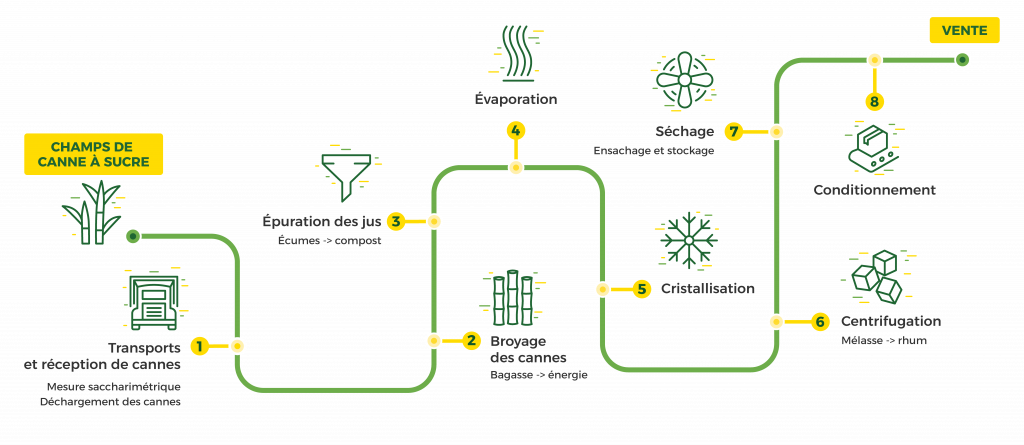

This is the crucial stage, around which the operators build up the grain to the desired size in successive cuites.

To generate crystallization, the first step is to seed the syrup with sugar dust, around which the crystal will form.

GARDELhas numerous cuites, some running continuously, others discontinuously, depending on the product required.

This stage, which requires highly specialized know-how, takes around 6 to 12 hours.

The result is a crystallized masse cuite: small crystals floating in a colored syrup.

Molasses is a by-product of the sugar depletion of crystallized syrups.

Composed of sugars such as glucose, sucrose and fructose,

molasses has always been used in the history of sugar.

molasses is mainly used in distilleries, where, after fermentation and distillation,

molasses is used to produce traditional sugar rum.

In large cylindrical dryers, the sugar is stirred with dry air to reduce its moisture content. Sugar must be perfectly dry to ensure it keeps well.

Raw sugars destined for refining in Europe are stored in bulk in our silo in Jarry, close to the port, to facilitate shipping. Sugars for direct consumption, also known as special sugars, GARDEL’s main product, are packaged in hermetically sealed one-ton big bags.

Our special sugars are then shipped throughout the West Indies and Europe in these big-bags or in 25kg bags, mainly to our food industry customers.

These same sugars are also the ones you find in your supermarket, packaged in 2kg to 500gr bags or even in 5gr brichettes.

Here’s a suggestion of pages to discover

all the skills and know-how that go into cane sugar.